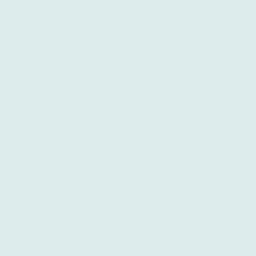

Commercial Max

For over four decades, the entirely fabricated and welded ‘Commercial-Max’ roof racks have set the standard of strength in Australia, offering individually designed mounting systems and custom platform dimensions tailored to specific vehicle makes and models.

Engineered for

• Tradespeople. especially those carrying bulky and heavier materials

Available For

• Most Vans, new and old

• Older 4wd vehicles

• UTE Canopies

Components

Cross Bars

19mm square welded to the outer frame at both ends.

Wind Deflector

Standard on all racks that need one.

Frame Rails

22mm square Galvabond material

Mounting Lugs

Attached to the roof sub-assembly and the rails are bolted to the lugs

Mounting rails

Laser cut from 3mm steel, zinc-plated and powder-coated

WHAT GOES INTO A COMMERCIAL MAX?

DEVELOPMENT AND TESTING

The Commercial Max was developed by our founders, Tradesman Roof Racks, in the 1970s to help tradies carry their loads to sites and adventurers to cross Australia. 45 Years later, the rack is still a workhorse used by thousands of traders across Australia. Specifically designed to carry large and awkward loads, the design has been changed many times over the years as vehicles have become more complex. One thing that has stayed the same is its rugged reliability.

COMPONENTS

This platform consists of

- 22mm Square outer ring

- 19mm Square crossbars

- 41mm x 22mm cross bar Channels

- Zinc electroplated/powder-coated mounting system

- Stainless and zinc mounting hardware

Galvabond Construction

Commercial Max platforms are manufactured using Australian-made Bluescope MSGB tubes. MSGB stands for Mild steel Galvabond, which is a tube rolled from a hot-dipped zinc-coated steel strip with zinc coating on both sides. This dramatically increases the durability of a commercial max roof rack’s finish. Further increasing the corrosion resistance.

Customisation

As All Commercial max roof racks are manufactured in our Bayswater, Victoria facility, they can be customised to your unique requirements. Whether for one vehicle or a fleet of fifty, Wedgetail Racks can custom manufacture this rack in many ways to suit your application. Feel free to contact one of our friendly and expert team for further details.

MOUNTING LUGS

The mounting lugs are used to attach to mounting points built into the sub-structure of the vehicle roof. Once the fixing lugs are installed the mounting rails are bolted to the lugs. The lugs are designed for individual models of vehicle and a variety of fixing devices are used for the lugs. Most vehicles with factory fitted rails will have bolt in points so they are used.

If bolt in points are not available we will drill through to the sub-structure of the roof and use stainless steel rivets to fix the tabs. All holes are then water proofed using a commercial grade silicon sealant.

MOUNTING RAILS

The mounting rails are custom-designed for each vehicle so that the weight of the platform and load is evenly spread over the vehicle’s roof. They are laser cut from 3 mm steel, zinc electroplated, and powder coated with a matt black finish. The mounting rails for all utes and wagons are a single piece, and for most vans, they are two pieces per side.

Nitty Gritty

The Commercial Max Roof Rack is the versatile, heavy-duty solution you’ve been looking for, proudly manufactured in Bayswater for over 40 years. Designed with tradespeople in mind, it’s ideal for transporting your equipment and materials, offering the perfect balance of durability, strength, and customisation to suit your daily needs.

Made from high-strength steel, this rack is built to handle significant loads while keeping your cargo stable and secure during transit. Whether transporting bulky tools or specialised materials, you can rely on its robust construction to deliver long-lasting performance in even the most demanding conditions.

As one of the last remaining Australian manufacturers of roof racks, we can customise your roof rack to suit your needs.

To ensure your roof rack lasts, the rack is manufactured from Galavabond (galvanised steel) using a specialist bronze welding process, which will protect against rust and corrosion. In addition, where required, your commercial max roof rack will be supplied with a wind deflector to reduce wind drag and noise, improving fuel efficiency and driving comfort—especially during long hauls or highway trips.

With its customisable design, weather-resistant finish, and easy installation, its is a reliable and efficient workhorse for any trade professional who needs a strong and adaptable roof storage system.

Tech Specs

| Steel Grade | Bluescope, Mild Steel Galvabond (MSGB) |

| Weld Grade | Bronze |

| Powder Color | Nightsky |

| Mount Material | Zinc Electroplated Mild steel |

| Hardware Material | G304 Stainless, Zinc |

| Customisation status | Customisable on request |

EXPERIENCE IT FOR YOURSELF

Commercial Max Platform to suit Caddy service body

$1,125.00

Commercial Max Platform to suit Caddy service body

$1,190.00